-

Posts

1,809 -

Joined

Content Type

Profiles

News

Store

Downloads

Everything posted by TRIFECTA Performance

-

Introducing the world's first All Wheel Drive (AWD) Chevrolet Sonic

TRIFECTA Performance commented on TRIFECTA Performance's article in News

Probably not. The Sonic was a perfect candidate for this given it and the Trax are both on the Gamma II chassis. While it wasn't a direct swap, it was no doubt exponentially easier than trying to do this with a Cruze. For the Cruze, we'd need to source a donor vehicle that uses AWD on the Delta II chassis, but unfortunately none exist. -

What is “Lean Cruise”? From the late 1990s through the mid 2000s there was this mysterious feature enabled in some non-US V8 (LS1) engine software calibrations that was purported to improve fuel economy. Some of the aftermarket calibration product suites referred to it as “Lean Cruise” and what it did was it allowed the vehicle to operate at fuel mixtures leaner than stoichiometry (14.7:1 air to fuel ratio on non-ethanol gas) under certain light-load conditions (such as steady state cruising) – generally up to 17:1 or 18:1. How does “Lean Cruise” improve fuel economy? “Lean Cruise” has positive impacts on fuel economy, but not largely for the reason most people think. It's widely believed that running a leaner mixture means less fuel is being consumed, and hence the fuel economy improves. This is true, but it is by far the smaller effect versus another: reducing pumping losses. Pumping losses occur, particularly on large displacement engines while the engine is under light load because a gasoline engine's power output is currently regulated by a throttle blade (though newer engine designs are beginning to use variable valve lift technology as an alternative). In the steady-state cruise scenario, the throttle blade needs to be mostly closed to maintain a specific vehicle speed. Because the throttle blade is mostly closed, the pistons operating on the intake stroke are literally fighting against the throttle blade to pull a full cylinder's worth of air in but cannot. “Lean Cruise” reduces pumping losses because it requires the engine to operate with the throttle blade opened further than it would otherwise if it were operating at stoichiometry. The engine cannot generate power as efficiently at leaner mixtures, so the engine needs to be operated under a higher load at the leaner mixture. Naturally, the LS1 engine was a perfect choice to implement “Lean Cruise” on. “Lean Cruise” is not allowed by US EPA / CARB regulations “Lean Cruise” was only enabled in certain non-US software calibrations where the emissions standards allowed it. Running the engine at a leaner mixture increases combustion chamber temperatures and dramatically increases the amount of “oxides of Nitrogen” (also known as NOx) emissions. The other emission-related issue is that the catalytic converters used on modern day vehicles, (also known as Three Way Catalysts) require the engine management software to oscillate the fuel mixture between slightly lean and slightly rich in order for it to be able to do its job. TWCs cannot function properly if the fuel mixture is run in the ranges that “Lean Cruise” utilizes. Newer engine designs lose the pumping losses benefit from “Lean Cruise” Remember what we said about pumping losses? GM's answer to that issue was to solve it using two other technologies (though only one of which is relevant to the LF4): 1. Variable valve timing (VVT), and 2. Active fuel management (V4 mode on the V8 engines). The LF4 enjoys a great benefit from VVT because both the intake and exhaust camshafts can be independently phased. Under light load cruising conditions, the engine control module (ECM) sets the camshafts for more “overlap”. “Overlap” is the amount of time both the intake and exhaust valves are open. By setting both valves to be open, instead of fighting against the throttle blade, the intake stroke can pull exhaust gasses back into the combustion chamber, thus reducing pumping losses with the added benefit of inducing Exhaust Gas Recirculation (EGR) which is also beneficial for controlling emissions. The other way VVT can help reduce pumping losses – a technique that is also used on the V8 engines, is by retarding the intake valve event such that it begins as late as possible after top dead center (ATDC). This effectively shortens the length of the intake stroke, and the engine spends less time fighting against the throttle blade. Active fuel management (AFM) further reduces pumping losses by effectively shutting off 4 of the 8 cylinders (though newer AFM designs allow for shutting off up to 7 cylinders). It does this by disabling the camshaft lifters on 4 of the cylinders, so those cylinders are no longer fighting against the throttle blade. This feature doesn't exist in the LF4, but newer V6 engine designs like the LGW, LGX and LGZ all can disable 2 cylinders on the fly. “Lean Cruise” was removed from OE software “Lean Cruise” disappeared from OE software when the newer series of engine controllers was developed starting with the Gen IV V8 in 2005. In 2006, the L76 engine was introduced. This was a 6.0L engine that had VVT – the first of its kind. Later variants of the Gen IV V8s such as the L94 and the L99 used VVT primarily to improve fuel economy by reducing pumping losses. It is clear that GM found better results with VVT than using “Lean Cruise” without having to maintain two different emissions standards and software calibrations for various regions. Any modern “Lean Cruise” implementation would require some trickery Because “Lean Cruise” as a feature hasn't existed in the operating system of the engine controller since around 2004, any implementation that attempts to mimic the effects of it would require some amount of trickery. It's certainly possible to calibrate the ECM to go into open loop fuel mode, and command leaner mixtures, but what are the possible side effects of that? One is that many of the ECM's diagnostics won't run if the commanded EQ Ratio isn't 1.0 (stoichiometry) and in closed loop fuel control mode. O2 sensor self tests, EVAP purge events, sensor plausibility checks are just a few examples of diagnostics that require the ECM to drive the mixture specifically to test that the engine is operating properly. Another IS that it cannot operate in closed loop fuel control mode if the commanded mixture isn't EQ Ratio 1.0. The fuel trimming system is designed to detect deviations in actual engine performance vs predicted engine performance, and provide a feedback-based correction mechanism. One more is that the TWC (catalytic converters) cannot operate properly while closed loop fuel control is disabled, and the vehicle would produce emissions in excess of the limits allowed by the US EPA and CARB. And last, running the engine at leaner-than-stoichmetric fuel ratios would cause combustion chamber temperatures to rise. Direct injected (DI) engines are already prone to a phenomenon called “stochastic pre ignition” (SPI) in which the fuel charge ignites too early. While the LF3 and LF4 seem to be relatively immune to SPI, it has been known to cause pistons to break between the ring lands on other GM turbo engines. The likelihood of an SPI event occurring would be increased by both increased combustion chamber temperatures and running a leaner mixture. A lopsided trade-off between benefit and concern As stated in the introduction, we won't be offering “Lean Cruise” on our products because we don't feel the trade-off between benefit and concern is a good one – largely because we have failed to find any substantial benefits at all. We have experimented with mimicking “Lean Cruise” in the newer engines and we haven't found any substantial fuel economy gains. We can't speak for claims that others are making but when we measured actual fuel consumption changes, the improvements were within the range of statistical noise. And this makes sense: when you consider the largest benefit “Lean Cruise” offers is reduction of pumping losses, the LF4's engine design itself (smaller displacement, turbocharged, independent VVT) does far more than “Lean Cruise” did back in the LS1 days. We'd also challenge anyone who is using a “Lean Cruise” tune to check actual MPGs versus what is reported on the instrument cluster. If a modern “Lean Cruise” implementation is reliant on trickery, it stands to reason this would skew the ECM's ability to estimate the fuel economy as well. Having said all of this, aftermarket engine calibration remapping is a dynamic process. We continuously challenge our previous notions in the light of what we learn along the way. It is possible one day we will make a discovery that changes the trade-off between benefit and concern.

-

The Sonic cousin: Buick Encore / Chevrolet Trax In a quest like this, the first thing to do is figure out which parts can be borrowed from other vehicles that have the feature you want. It turns out the Chevrolet Sonic, Chevrolet Trax, and Buick Encore all share something in common: the chassis. Known as the GM “Gamma II” chassis, it started in the US in 2010 as the Chevrolet Spark. In 2011 the Chevrolet Aveo was introduced. In 2012, the Aveo was renamed as Sonic, and in 2013 the Buick Encore and Chevrolet Trax were introduced with optional AWD. The Sonic, Encore and Trax use the 1.4L turbo MPFI engine (RPO: LUJ/LUV). Borrowing the AWD System For our project, we obtained a 2015 Chevrolet Sonic RS and an AWD Chevrolet Trax. The Chevrolet Trax has a transverse mounted 1.4L turbo engine, mated to a 6 speed automatic transmission. A transfer case attached to the transmission sends power to a rear differential via a propeller shaft. An ECU (Rear Differential Clutch Control Module) controls the amout of torque transferred from the propeller shaft to the rear differential. Not as easy as it Sounds Given these vehicles are all “Gamma II” chassis vehicles, we just need to unbolt the AWD system from the Trax and install it in the Sonic, right? Not quite. To name just a few challenges: We had to cut the spare tire well out of the Sonic to make room for the rear differential. We had to swap the rear suspension from the Trax in its entirety because the Sonic suspension doesn't have a provision for the propeller shaft. The propeller shaft will need to be shortened. Maybe a Rally Spec car instead of a Hot Hatch One other issue we've run into so far, is that the Trax suspension sits higher than the Sonic suspension. The overall ride height will be about 1.5” higher than the original suspension. Maybe we should make this into a Rally spec car instead of a Hot Hatch!

-

Control your Boost Turbocharged engines rely one of a few different methods of controlling the boost level. Most modern-day gasoline engines rely on a “wastegate”, while diesel engines generally rely on Variable Geometry Turbochargers (VGT). In both cases, boost pressure and airflow is the result of engine exhaust gasses passing through the turbine of the turbocharger, of which the compressor shares a common shaft. Hence, turbine acceleration causes compressor acceleration which causes boost pressure and airflow to rise. With a wastegated turbocharger, the turbine and compressor speed are controlled by allowing a variable amount of engine exhaust gasses to bypass the turbine. With a VGT, the angle and shape of the turbine vanes can be changed on the fly, which affects the speed of both the turbine and compressor. VGTs are considered to be more efficient as the turbocharger's mechanical characteristics can effectively be changed, on the fly. (As an aside, the reason VGTs aren't prevalent on gasoline engines is because the exhaust temperatures tend to be much higher, although materials technology has caught up and VGTs are slowly making their way into high end gasoline engined vehicles like the Koenigsegg One:1) Wastegated Turbochargers The remainder of this article will focus on wastegated turbochargers (specifically internally wastegated turbochargers), since that is the type that is used in on the 1.4L turbocharged engine. In the age before Electronic Control Unit (ECU) controlled engines, the original wastegated turbochargers used a purely mechanical approach to controlling the boost. A calibrated “wastegate actuator” (WGA) would use spring pressure to hold the wastegate “default-closed”. Exhaust pressure levels “pre-turbine” (in other words, the exhaust pressure between the exhaust port and the “front side” of the turbine) rise in accordance with boost levels, and once there is sufficient pressure on the wastegate to overcome the spring weight in the WGA (sometimes called the cracking pressure), the wastegate will start to open and allow exhaust to bypass the turbine. This regulates boost pressure and airflow. LUJ/LUV Turbocharger turbine and internal wastegate (wastegate closed) LUJ/LUV Turbocharger turbine and internal wastegate (wastegate open) In the age of purely mechanical wastegates, it was relatively easy to increase boost levels beyond OE design specifications – all one had to do is install a heavier spring in the WGA, and the cracking pressure would increase, which would cause the turbine to spin faster, which in turn would cause the compressor to spin faster and compress more air. Of course, fueling and ignition advance curves would have to be modified, not to mention charge cooling systems as increasing the boost would also increase the amount of heat generated from compressing the incoming air. ECU Control – A Twist on Mechanical Wastegates When ECUs started managing engine operation, engineers had to come up with a method that would allow the boost to be regulated electronically, and, additionally through a closed-loop feedback system that would allow the ECU to compensate for changes in environment (air temperature, altitude, fuel quality) as well as changes to the engine operation as it wore mechanically. The earliest turbocharged engines from General Motors utilized a similar WGA as was from the mechanical days, with a twist: the addition of a pressure reference port which could effectively lower the WGA cracking pressure by applying pressurized air. LUJ/LUV Wastegate Actuator (WGA) In this system, there is also a boost control solenoid (BCS) which is essentially like an electronic diverter valve. By providing a Pulse Width Modulated (PWM) signal from the ECU, the ECU can control how much of the boost pressure coming from the compressor is allowed to be directed to the WGA. On General Motors vehicles, the usable PWM duty cycle range is 5% to 95%, where 5% causes the maximum amount of boost pressure to be directed to WGA, and 95% causes minimal amount of the boost pressure to be directed to the WGA. In other words, when the BCS command is 5%, the lowest amount of boost will be produced, and when it is 95%, the highest amount of boost will be produced. The following pictures show the BCS on the LUJ/LUV engine: LUJ/LUV Boost Control Solenoid (BCS) The ECU determines the “desired boost” level based on myriad decision inputs, including calibrated power limits, calibrated powertrain component limits (e.g. maximum turbocharger compressor speed), driver power demand, altitude, incoming air temperature, amount of historical knock, just to name a few. Once the ECU makes a decision on the boost level, it references a calibrated table to decide how much duty cycle should be output to the BCS, and drives (commands) the BCS to that duty cycle. The ECU then monitors incoming air mass via the Mass Air Flow (MAF) sensor, the intake Manifold Absolute Pressure (MAP) sensor, the Throttle Inlet Absolute Pressure (TIAP, or “boost”) sensor, and several Intake Air Temperature (IAT) sensors to determine if the turbocharger is operating as desired. If the actual boost level is lower than the desired boost level, this is considered an “underboost” condition and the ECU will make some dynamic increases to the BCS signal to try to correct the condition. If the actual boost level is higher than the desired boost level, this is considered an “overboost” condition and the ECU will dynamically reduce the BCS signal to try to correct the condition. In an overboost condition, it may take further, more drastic measures depending on the severity of the condition such as shutting down boost entirely, closing the throttle blade, or opening the bypass valve. This is done to protect the engine and its components (more on these conditions later). The ECU employs a Proportional-Integral-Derivative controller (PID controller) strategy to both immediately correct boost control errors, and also correct predicted future boost control errors. This is the “closed loop” portion of the system. The parameters of this system are part of the ECU calibration and can be modified as needed. This article won't go into depth regarding how a PID controller works, but there's a great reference on Wikipedia (https://en.wikipedia.org/wiki/PID_controller) that describes both the method and the mathematics behind it. Advancements in ECU Turbocharger Controls Since the original boost control system design on General Motor vehicles, two variants have come along. The first is used on the twin turbo V6 engines (RPO: LF3, LF4 and LGW). The system works very similarly to the “default closed” systems originally used, but in this case, the wastegates are “default open”. Mechanical spring pressure holds the wastegate open until boost is required. The advantage with this system is it allows for more efficient engine operation. If you consider the “default closed” system design, one drawback is the exhaust gasses are ALWAYS flowing through the turbine. Even under light duty, even where no boost is requested by the ECU, the exhaust still flows through the turbine, and the turbine still acts as an exhaust restriction, which reduces efficiency. The only way the wastegate can be opened is for the mechanical spring pressure to be exceeded, which can only happen when there's sufficient boost. The “default open” design aims to resolve this shortcoming. Instead of using positive pressure (boost) to control the WGA, negative pressure (vacuum) is used. When the WGA is subjected to atmospheric pressure, the wastegate is fully open. As the pressure supplied to the WGA drops, it starts to pull against a spring inside the WGA to close the wastegate. The negative pressure is generated by a mechanical pump driven by an engine component, and is controlled using a BCS which directs a controlled amount of vacuum to the WGA. It is essentially the inverse of the “default closed” system design. LF3 turbocharger with “default open” wastegate design This system is not without its drawbacks, however. It's significantly more complicated than the “default closed” system design because it relies on a system of vacuum pumps, lines and solenoids to control the turbocharger. Another interesting issue that has arisen on this system is the turbochargers can be noisy. The wastegate valve itself is a floating valve attached to the wastegate actuator arm. When the wastegates are open, they have a tendency to create an annoying rattling sound, and because the aim of the design was to keep the wastegates open under low power levels and at idle, the sound can be easily heard. General Motors even revised the turbocharger assembly several times in order to correct the problem. This cannot be an issue on “default closed” systems because the wastegate valve would be held against the wastegate orifice under these light load and idle conditions. But, on the very newest turbocharged engines General Motors is producing, such as the new 2.0L turbocharged engine (RPO:LSY), its larger 2.7L cousin (RPO: L3B), and the new 4.2L twin turbo V8 engine (RPO: LTA a.k.a. “Blackwing”), there's an exciting new technology being used! Doing away entirely with all of the pressure-based controls, the ECU now simply drives what is essentially the equivalent of a throttle blade actuator which directly drives the wastegate position. It also uses the “default open” design to improve efficiency. The aftermarket has not yet delved into calibrating any of these engines, so little is known about how effective this new solution is. Limitations with the Gen 1 1.4L Turbo Engine Wastegate System Now, we will discuss the specific issues with the LUJ/LUV engine turbocharger's wastegate system. The main issue we have observed is there can be quite a variance in the cracking pressure of the OE WGA assembly. Based on our years of experience in calibrating these vehicles, we can say that on average, a safe assumption is that the highest boost level that can be had on the OE WGA assembly, at sea level is around 20-22psi of boost. However, we've have also seen OE WGA assemblies that will support more than 25-26psi of boost. Our assumption is that because these vehicles, in stock form were never designed to make these kinds of boost levels, perhaps the manufacturing tolerances in the OE WGA is somewhat lax. When calibrating customer vehicles, however, we have to start with the lowest common demoninator or else our customers could end up with boost control diagnostic failures and subsequent “boost limp mode”. Collection of LUJ/LUV WGAs that all have different cracking pressures Adjusting OE WGA “Preload” a.k.a. “Playing With Fire” One of the classic (or perhaps “infamous”) techniques for changing boost levels (particularly before boost levels were managed by an ECU) was to adjust the length of the rod from the WGA to the wastegate arm. The original intent of using an adjustable rod length was to allow calibration of the wastegate but hot-rodders quickly figured out if they shortened the length of the rod, they could either restrict the amount the wastegate could open, or otherwise cause the cracking pressure to go higher (because of the additional preload on the spring). On the LUJ/LUV engine, indeed an adjustable length threaded rod is used between the WGA and the wastegate, but the factory attempts to prevent tampering by using some sort of locking compound on the threads. This isn't enough to stop a dedicated tinkerer, but we wholly recommend AGAINST modifying the length of this arm for the simple reason that it can cause the turbocharger to overspin which leads to either a failed turbocharger assembly, or a failed engine. LUJ/LUV WGA showing tamper-resistent compound on actuator arm adjustment Additionally, changing the WGA rod length will have no effect on the boost potential without corresponding tuning changes because the ECU will detect there's more boost than expected and simply respond by either commanding less BCS duty cycle, or closing the throttle. Introducing the Forge Billet WGA for the LUJ/LUV Forge is an aftermarket UK company that specializes in engineering and manufacturing aftermarket WGAs (among many other parts). They have developed a billet aluminum WGA for the LUJ/LUV engine (Forge part number FMACC14T). One of the fascinating features of their part is the mechanical cracking pressure can be adjusted through the use of interchangible springs. Through our testing process, we found their part to be incredibly consistent from unit to unit (unlike the OE WGA) and of high quality. Forge Motorsport FMACC14T w/ “Yellow” spring pre-installed When you purchase this WGA from Forge, off the shelf it includes a “green” spring pre-installed in the WGA. We found this spring to be too “light” - in other words, the cracking pressure was actually LOWER than the OE WGA. We tested the next heavier spring, which is the “yellow” spring, and found it to be a suitable choice for the LUJ/LUV in that it allows boost pressures to reach the potential of the engine and OE turbocharger closely. We could have, of course, chosen an even heavier spring (such as the “red” spring). However, there is a trade-off using a heavier spring that needs to be recognized. Not only does the heavier spring weight raise the cracking pressure of the wastegate (e.g. the MAXIMUM potential boost level), but it also, in effect, raises the MINIMUM pressure that can be made from the turbocharger when 100% of the pressure is being sent to the WGA (e.g. 5% duty cycle). The OE WGA has a minimum of around 5psi of boost, but the Forge WGA with the “yellow” spring is closer to 12psi. We chose the “yellow” spring because it's the lightest spring that can allow the maximum boost potential to be reached which in turn raises the mininum boost by the lowest amount possible. If the minimum boost level is raised too far, it can cause a clunky driving experience, because the ECU will have to manage the torque by closing the throttle blade instead of being able to open the wastegate. Forge Motorsport WGA installed on LUJ/LUV turbocharger So, what about the power? We recently performed a series of tests on one of our development vehicles. It is a 2016 Chevrolet Sonic LT, with the LUV engine, and a manual transmission. It has the following modifications: 60 lb/hr fuel injectors RacerX cold air intake SPEC billet aluminum flywheel WaveTrac Limited Slip Differential (LSD) TRIFECTA calibration Out of the LUJ/LUV vehicles we have at our disposal, this one was closest to stock configuration, and the few modifications it does have would not materially affect the power output, except for perhaps the flywheel. As expected, on the stock calibration (adjusted for the 60 lb/hr fuel injectors), this vehicle baselined at fairly high numbers on our dyno: Peak power output was 135 horsepower (HP) at the wheels (WHP), and 151 lb-ft torque (TQ) at the wheels (WTQ). Considering this vehicle is rated at 139HP / 149TQ at the flywheel from the factory, it would seem indeed the aluminum flywheel had a positive impact on power output for this vehicle. TRIFECTA Calibration with the OE WGA As started above, we consider 22psi (at sea level) to be the highest boost level that can be achieved on the OE WGA. This dyno chart shows what 22psi on this vehicle produced versus the OE calibration: Under these test conditions, PEAK gains went up by approximately 26WHP and 47WTQ. However, particularly with horsepower levels after the curve, gains are much higher than 26WHP – e.g. at 6300 RPM, the gains are closer to 45WHP. High RPM power delivery holds much further into the high RPM range than on the OE calibration. TRIFECTA Calibration with the Forge WGA and “Yellow” Spring Finally, we tested the vehicle and calibrated it to its full potential with the Forge WGA. Observe the following dyno chart: Versus the OE WGA, we gained another 17WHP, and a whopping 33WTQ! The torque gains are so impressive because this engine can really utilize boost levels higher than 22psi at the low to mid RPM range. Choosing some key RPM points, the following table summarizes the gains that were possible with just tuning and the Forge WGA: 3500 RPM 5500 RPM 6000 RPM 6300 RPM OE WGA / Calibration 146WTQ 133WHP 123WHP 115WHP OE WGA / TRIFECTA (22psi) 190WTQ(+44) 155WHP(+22) 143WHP(+20) 141WHP(+26) Forge WGA / TRIFECTA 229WTQ(+39/+83 total) 166WHP(+11/+33 total) 157WHP(+13/+33 total) 156WHP(+15/+41 total) More than just Power Believe it or not, the vast majority of calibration work required to make the Forge WGA work correctly has nothing to do with getting the big power gains. Because the turbocharger response from the BCS was dramatically altered with the installation of this part, we needed to start from scratch in dialing in the BCS table and the other PID controller constructs. We've spent about a week of total time on the dyno with various LUJ/LUV vehicles just getting everything mapped correctly. Without proper calibration work, people installing this sort of part are likely to have sporadic, or even common issues with “boost limp mode”. This is where the ECU detects that there's been an ongoing boost control problem for long enough that it shuts down the boost control system entirely. This results in a maximum boost level of about 12psi (or 5psi on the OE actuator) and a very powerless vehicle! - TRIFECTA Performance

-

Tuning Buick Regal's Sport and GS Mode

TRIFECTA Performance commented on TRIFECTA Performance's article in News

Hey Wes, we are focusing on 2014--2015 Regal LTG for now, but we'll open it up to more model years after this first round. -

Buick Regal GS and Sport Modes Certain models of the 2011--2017 Buick Regal vehicles are equipped with additional mode buttons – one is labeled “GS” and the other is labeled “Sport”. Depending on the features of the vehicle, these buttons may change the way the suspension operates, the way the accelerator pedal responds, and/or the way the automatic transmission shifts. TRIFECTA Exclusive Driver Selectable Vehicle Modes (DSVM) One of the earliest exclusive TRIFECTA product features is DSVM, formerly known as Select-A-Tune (SAT). Taking root in the days of the first 2.0L turbo Direct-Injected engine GM built (RPO: LNF), SAT was a feature designed to give the driver dynamic control over the vehicle's power output. This feature was a very popular distinguishing feature of the TRIFECTA calibration. Over time it evolved into DSVM by name, and has been implemented in most vehicles that TRIFECTA offers a calibration for. DSVM and SAT are exclusive because they rely on the specific software that doesn't exist in the OE software. Some vehicles have OE DSVM-like capabilities, such as the 2014-2019 Chevrolet Corvette, but many other vehicles do not. Buick Regal GS and Sport buttons TRIFECTA has always been interested in whether either (or both) the GS and/or Sport buttons found in the Buick Regal could be tapped into to change the engine's dynamics on the fly. After some amount of research we determined that these buttons can in fact be used to select alternate automatic transmission shift profiles, but selecting alternate performance envelopes and pedal response maps seemed to not be possible with the OE software. Bringing DSVM to your Buick Regal GS and Sport button TRIFECTA is proud to announce we have successfully developed the Driver Selectable Vehicle Modes feature for the 2014--2017 Buick Regal, bringing about the ability to change the power and drivability dynamic of their Buick Regal on the fly with the GS and/or Sport button! Changing modes via the arming state of the Cruise Control system In developing this feature, we realized our customers who may not have the Sport or GS modes on their vehicle may want to take part in the fun. With that in mind, we've taken things a step further and have integrated the ability to switch modes based on the arming state of the Cruise Control button as well! Now Regals without the GS/Sport buttons can also enjoy this feature! When purchasing or updating an existing purchase, customers are now able to select how they want the TRIFECTA calibration to be activated. The available configurations are: None ("Always On") GS Mode Sport Mode GS or Sport Mode Cruise Control Disarmed If you already have a TRIFECTA calibration for your Regal, all you have to do to request this update is log in and update your purchase here: https://www.trifectaperformance.com/clients/purchases Simply select your purchase, update the form, and click save. Your update will be queued up and written in the order it was received! If you have any questions about this feature, please feel free to reach out to us: Contact Us!

-

TRIFECTA 2018--2019+ Buick Regal Sportback / Avenir / TourX 2.0L Turbo 8-speed and 9-speed automatic Detailed power gains (measured at the wheels, dynojet chassis dyno) 2.0L gains: up to +48 ft-lbs torque, +49 horsepower (peak gains of up to 43 ft-lbs torque, +42 horsepower) TRIFECTA's 2018--2019+ Regal recalibration is complimented by a fully developed 8-speed (TourX) and 9-speed (Sportback/Avenir) automatic transmission calibration to support the increased power delivery profile and to offer dramatically improved driving characteristics from everyday driving maneuvers. The complete powertrain calibration also includes ESC (Stabilitrak) program enhancements. Specifications of the TRIFECTA Performance 2018--2019+ Regal ECM software reprogramming: -Fuel economy is improved dependent on fuel grade and driving conditions -Retains all GM OE diagnostics and ECM functionality -Retains all OE error code reporting and functionality -Emissions readiness checks are present; emissions compliant -Maintains functionality of ABS and TC systems -Knock detection mechanisms and OE engine knock detection sensitivity is retained -Return to stock functionality included with flash loader -Tested on all available grades of fuel (87, 89, 91, 92, and 93 octane). TRIFECTA Driver Selectable Vehicle Modes (DSVM): Modify driving profiles based on the cruise control enable setting (vehicles equipped with cruise control only) Standard Mode: Cruise Control ON (armed) = Vehicle responds to pedal input and shift logic similar to factory programming TRIFECTA Sport Mode: Cruise Control OFF (disarmed) = Vehicle responds more aggressively to throttle input, shifts are optimized for performance TRIFECTA Performance Auto Stop Mode (PASM): Allows the driver to enable a performance-oriented auto-stop mode which, in most cases, inhibits auto-stop from enabling for improved performance character, when desired (triggered by the cruise control arming button) Specifications of the TRIFECTA Performance 2018--2019+ Regal 8-speed (TourX) and 9-speed (Sportback/Avenir) automatic transmission TCM calibration software reprogramming: -Regal Sportback/Avenir models with 9-Speed automatic transmission w/ T87A transmission control module (TCM) DO NOT require the TCM to be removed from the vehicle and mailed in to be "UNLOCKED". -TourX models include industry exclusive support for 8-Speed Aisin AF50-8 transmission (RPO: MRC) -Improved shift times in adverse shift patterns -Improved shift logic - shifts are progressive and purposeful -Does not shorten transmission life or increase cooling requirements -Retains all OE diagnostics and TCM functionality -Retains all OE error code reporting and functionality Installation Notes: -Estimated installation time of ~20 minutes -Premium fuel is recommended for maximum power output, but not required Dyno-proven gains: Using industry standard chassis dynamometers, TRIFECTA shows proven gains in torque and horsepower for your Buick Regal, using only the factory hardware (2018 Regal Sportback FWD): Additional information and availability: - This powertrain calibration includes a TRIFECTA powertrain calibration file specific to your vehicle and includes a flash loader device - Powertrain calibrations currently exist for North American vehicles only, with more regions to follow - Advertised gains are quoted as 'up to' and may be less for a vehicle operated at altitudes higher than near sea level. The TRIFECTA Autostop Delete Powertrain Calibration is meant for 100% stock vehicles. No individualizations or support for parts that do not function on factory calibration (if you have such modifications, be sure to check with us prior to placing order). The TRIFECTA Advantage Calibration is meant for 100% stock vehicles. No individualizations or support for parts that do not function on factory calibration (if you have such modifications, be sure to check with us prior to placing order). The TRIFECTA Elite Calibration offers premium tier-1 support. With this product, customers can request specific calibration changes and support for third party hardware. Remote-tuning services are offered with this tier. See this product in our store! https://www.trifectaperformance.com/store/category/1877-20l-turbo-2018-present/

-

Serving the Community First, and Continuous Improvement

TRIFECTA Performance posted a article in News

Background A TRIFECTA Chevrolet Equinox calibration customer of about a year contacted us about his other car, a Chevrolet Cruze which was tuned by another company. He stated he was having issues with it going into “limp mode” under various conditions and setting various diagnostic trouble codes (DTCs). After some discussion, we learned he was within a few hours' drive of one of our R&D centers, so we offered to investigate the issue for him at no charge, as a courtesy. Full Vehicle Inspection One of the concerns we have when challenges like this arise is the breadth of issues that might have arisen on the vehicle. This is a vehicle that's over 5 years old, and has around 100,000 miles on it. It's been modified, and has unusual issues with it. So, we told the gentleman that the first thing we were going to do is perform a full inspection on the car, on a lift to look for anything that might be causing or contributing to the issues and if we had any reservations based on what we discovered whatsoever, we may not be able to proceed. This car turned out to be in excellent condition for its vintage. The only issue we found was a slight oil leak on the oil pan, but overall it was in very good condition and had been well maintained. Data Collection After passing the inspection, we put the car on the chassis dyno to observe how the current tune on it was running and what was going on with it, but before doing so, we checked to see how the wastegate actuator was set up. This aftermarket part is adjustable, and if adjusted incorrectly for how the calibration is written, it can cause boost control errors (overboost or underboost) which generally leads to “limp mode”. After confirming the wastegate actuator required no adjustment, we proceeded with studying the vehicle's operation on the dyno. Here's the full dyno pull: Our general consensus was this is a decent tune – power delivery was smooth, good AFRs, no knocking, etc. However, we discovered that the ECM was closing the throttle blade because the turbo was generating more boost than it was supposed to (overboost). This caused a power drop (see red circle). After further study of the data from the vehicle under various operating conditions, we found it had a general overboosting problem and suspect this was at least a contributing factor to the “limp mode” issues the vehicle owner had experienced. Starting from Scratch Our commitment to the vehicle owner was that, if both, after the vehicle passed inspection, and after reviewing the data we felt it was something we might be able to fix in the calibration, we would start over from scratch with the TRIFECTA production calibration for this vehicle, work to confirm proper boost control with the wastegate actuator, and then see where we could go with it power-wise with our margin of safety and reliability in mind. Here's what the production TRIFECTA calibration vs the tune it came in with (red vs blue) did with the wastegate actuator settings incorporated, but the power level settings set for the stock wastegate actuator: The TRIFECTA production tune carried the power further into the power band at higher RPM, delivering an almost 8 horsepower at the wheel (whp) gain, but had lower torque and horsepower output because it was calibrated for the OE wastegate actuator. Dialing it In Remember, the original issue the vehicle owner had wasn't with the power. It was with the fact it was going into “limp mode”, so our goal wasn't immediately to shoot for the moon on power. Rather, it was to determine if we could get the boost control accurate enough so we could be sure the vehicle would behave correctly if everything is in working order. We had previously spent a solid week on the dyno (and much more testing under regular driving conditions) with our own vehicles to develop TRIFECTA support for the Forge wastegate actuator with the yellow spring (and its derivatives), so we had a proven calibration to start with. There had been some concern that the wastegate flow characteristics on this vehicle weren't entirely the same as some of the other vehicles with the same engine. As such, we did notice some subtle overboosting at 50% pedal, on the dyno, even with our wastegate actuator settings: The green line (actual boost pressure) should always be below, but near the blue line (desired boost pressure). As you can see here, the green line was slightly above the blue (indicating an overboost condition), particularly near the end, just prior to the blue and red (manifold absolute pressure) lines drop off, which is where the pedal was released. The overboost is only about 13kPa here, but given overboosting was a primary concern for the vehicle, we made some adjustments to get the green line below the blue one (this is a full dyno pull): There is still a very slight overboosting on spool up, but that is considered acceptable by the ECM. After that, you can see the green line stays right on or slightly below the blue line now. No more overboost! The Dyno is One Thing, the Street is Another A chassis dyno is an incredibly useful tuning tool, and the dynos that have the eddy current loading system are even more invaluable for simulating various load conditions. However, street testing is crucial, and with an issue like this where the vehicle “limps out” under various conditions, the street testing is, in reality, even more important. So, we took the car for an hour long drive on the street. Residential areas, highways, downhill, uphill, corners, driving lightly, driving aggressively, winding the RPMs out, lugging the engine, everything we could to test out our boost control settings. Not once did we encounter a “limp mode” event. Having declared the wastegate settings correct, we moved on to the next step! Shooting for the Moon Now for the fun part! By now we were convinced the boost control was correct on the car, so we decided to see what we could do power-wise with the setup. By making some power limit adjustments that could take advantage of the upgraded wastegate actuator installed on the car, we made some really nice improvements in power over both the tune it arrived with and the TRIFECTA production calibration! See here: As a refresher, blue line is the tune the car came in with, red was the TRIFECTA production calibration, and green is the TRIFECTA production calibration plus tweaks for the upgraded wastegate actuator (which the tune the car came in with had also). There were improvements in every part of the power band, with the various hightlights: Spool up RPM (2000-3200 RPM): +10 lb/ft torque up to +22 lb/ft torque Peak Torque RPM (3650 RPM): +16 lb/ft torque Peak Horsepower RPM (5700 RPM): +22 horspower Happy Customer, Good Times The vehicle owner was very pleased with not only the power gains, but also that we had simultaneously resolved the “limp mode” issues to a large degree and introduced a new quality of refinement and smoothness to the way the vehicle drives on the street. Time will tell if it's truly resolved, but we will continue to actively follow up with the vehicle owner and collect additional data as needed. This was also a rare opportunity to meet a member of the Cruze car enthusiast community we consider ourselves proud to serve. We ripped around in the car, had lunch, traded ideas for car modding, joked about life in the automotive business, and just plain old had a good time. Continuous Improvement We regard every opportunity we are privileged with to work with customers directly an opportunity to improve our knowledge, experience and calibration techiques. Thanks to the owner of this Cruze, and his familyfor taking the time to be involved in this project, we learned some things that we believe will lead to improvements in our production level products as well. Namely, we believe some (likely not all) of the gains we found as we optimized the torque and horsepower bands for the upgraded wastegate actuator may be possible to a certain extent on the OE wastegate actuator as well. And we learned how some of the wastegate ports can flow differently from one turbo assembly to another. Everything we learn along the way becomes part of the product updates we release in the future, to our customer base. -

Hey @Gun3214, This is an in-house development project designed to showcase what can be done with the Cruze, but also a learning exercise for us as there were many engineering and calibration challenges that needed to be solved along the way. As with any hardware project we undertake, we may always consider bringing a big project to market if there were sufficient demand for it!

-

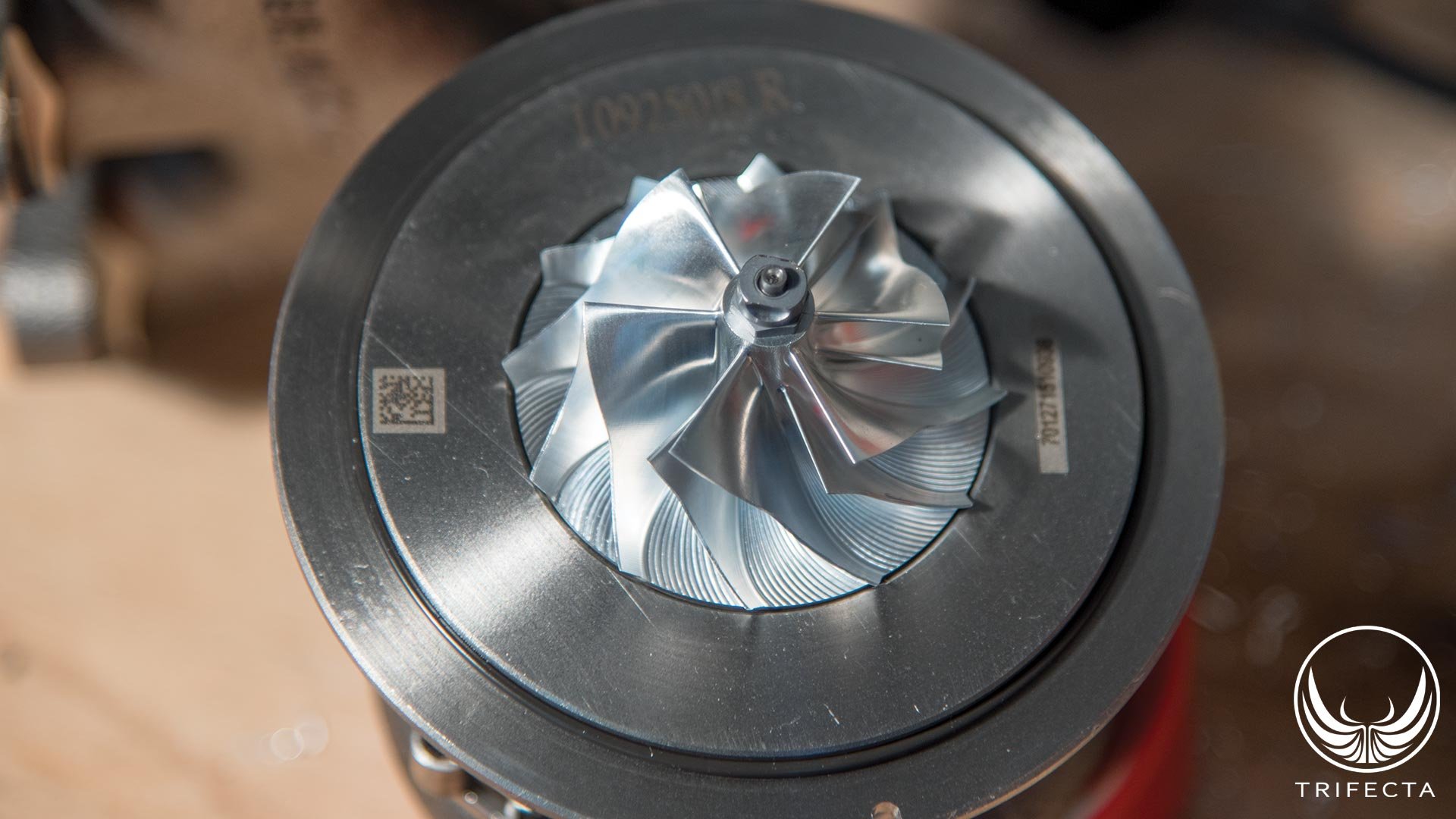

The LTG Engine Introduced in 2013 with the then-new Cadillac ATS, and also in the “Gen 8” Chevrolet Malibu, the “clean sheet” redesign of GM's “large” 4 cylinder turbocharged engine, the LTG engine was one of the most exciting developments to come along from GM! The LTG engine basically shares nothing in common with the outgoing LDK / LHU 2.0L turbocharged engine. It's so radically different, in fact, that the engineers changed the direction of the head flow on the LTG as compared to the LDK/LHU. LNF Engine in Cobalt SS On the LTG engine (in a front-wheel-drive application), the intake ports face the firewall, and the turbocharger faces the radiator. This is “backwards” from the flow of the LDK/LHU. In our opinion, this decision makes sense, because the turbocharger can benefit from airflow from the front of the vehicle in this configuration (ironically though, the LTG's successor, the LSY engine has reversed the head flow back to the same configuration as the LDK / LHU). LTG Engine in Camaro Aftermarket Development The unfortunate part about a “clean sheet” redesign is it frequently antiquates most or all investments the aftermarket might have made in similar engines. For example, by the time the LTG arrived and the LDK / LHU was beginning to be phased out in production vehicles, there was an extensive aftermarket parts market for these earlier engines (particularly the LNF, of which the LDK / LHU derives from). But almost none of those parts could be used to modify an LTG engine. Fastforward six and a half years from the time the LTG vehicles arrived on the market, and now there's quite a variety of parts in the aftermarket! Everything from intercoolers, intake systems, to turbocharger upgrades, and fueling upgrades (injectors, pumps, etc.), and it's shaping up to be a very exciting time for the LTG! Big Turbo TRIFECTA has been working on a Borg Warner EFR 7670 swap for the RWD Alpha chassis vehicles for some time. The most recent official dyno numbers we've seen on a 2017 Camaro with the 8sp automatic transmission is about 470WHP, but unofficially we've seen as high as 490WHP, on 92 octane pump gas. Big Turbo Camaro on the dyno This swap kit includes an integrated exhaust manifold that is one piece, from cylinder head, to turbocharger turbine. The exhaust side is located to OE coordinates, and the exhaust flange is the same as the OE LTG turbo exhaust flange. Existing exhaust components can be used with this swap kit. Factory turbo vs EFR7670 turbo The swap kit retains the electronically controlled bypass valve, and features a high pressure integrated wastegate. At this power level, we are using aftermarket camshafts with a “fuel pump lobe” to stretch the capacity of the OE high pressure DI (direct injection) pump. How about some E85? Any guesses on where the power will go with E85? We've installed upgraded fuel system components to help support the additional volume of fuel we'll need to run E85, maybe we can reach 550WHP, or maybe even 600WHP! Upgraded High Pressure Fuel Pump Stay tuned!

-

“Canned” tuning defined The clearest example of a “canned” tune is the off-the-shelf handheld programmer that you can buy at, say, the local autoparts store. This is a device that contains a pre-written tune for a vehicle (or many vehicles). Basically, you plug it in, the programmer reads out your OE calibration, makes changes to it, then writes (flashes) it back to the vehicle. In some cases, you may have limited options for adjustment, like to adjust the speedometer calibration for different sized tires. This type of tuning is generally designed for stock vehicles, or vehicles that have modifications that are compatible with the OE calibration. Benefits: 1. Easy to use 2. Low cost 3. Able to make limited adjustments 4. Great for “casual” tuning customers that want a performance boost without a bunch of hassle Drawbacks: 1. Can't support major modifications out of the box** 2. Tuning is generally more conservative because of vehicle to vehicle variances 3. The engineers that developed the calibrations may have more generalized tuning expertise 4. Little recourse if the vehicle doesn't operate properly for some reason “Canned” tunes are generally considered “mass market” in that they appeal to a wide variety of customers. They are generally less expensive than “customized” tuning, and easy to install by the end customer. However, they are largely for stock or lightly modified vehicles (e.g. you're unlikely to find an off-the-shelf programmer that has built in support for an aftermarket cam in your Corvette). In designing a “canned” tune, one has to consider the range and condition of vehicles it might be run on, and this means the tuning “aggression” may be lower. Calibration engineers that develop these calibrations may have a more general set of tuning skill as opposed to expertise in a specific vehicle. Lastly, what do you do if the vehicle doesn't run right, or has a problem? About the most you can do is uninstall the programmer and return it for a refund or sell it to someone else. ** - some of the programmers on the market can also receive customized tuning from network tuners “Customized” tuning defined “Customized” tuning, on the other hand, involves the iterative process of making tuning changes, collecting data (via “datalogging”, wideband, dyno, etc.), and then making further adjustments until the calibration is deemed “complete”. This process involves the use of commercially available calibration software to make the iterative changes. The process is executed either by an end customer with tuning expertise or by enlisting the services of a “tuner”. Benefits: 1. Capable of supporting almost any modification the tuner has expertise in 2. Tune can be “individualized”, or “dialed in” for a specific vehicle in a specific locale 3. Higher level of customization is possible (virtually any parameter can be customized) 4. Comprehensive performance data can be available Drawbacks: 1. More expensive (up to 4-5 times), more time consuming, may need “retuning” later 2. No common standard of quality in the end product 3. Limited by the capabilities of the software being used 4. Tuning process may include elements that aren't understood by the tuner The “customized” tuning process generally happens one of a few ways. One way is a customer brings a vehicle to a performance shop for a “dyno tune”. Another way is a customer meets up with someone locally who has the tuning software. The third common scenario is “remote custom tuning” where the customer works with a tuner in a remote location, generally over the internet to go through the iterative tuning process. Most “heavy modifications” like forced induction conversions (e.g. supercharger or turbocharger kits), camshaft changes, or other engine internal changes require extensive recalibration in order for the vehicle to operate properly. Many of the larger forced induction kit manufacturers include some sort of calibration for the kit (and in some cases it may even carry a CARB EO number). A performance shop may install the kit, the calibration, then “dial it in” as needed. In other cases the performance shop may have to tune the kit from scratch, starting with the OE calibration which can be time consuming. In almost every case, with “customized” tuning, the tuner has greater access to tuning customization because in theory any parameter can be modified with the software. With an off-the-shelf programmer, for instance, you might be able increase the transmission shift firmness in a general way, but with a “customized” tune you can be more specific and adjust the shift firmness only on the 2-3 shift at part throttle. And, because the “customized” tuning process relies on iterations of data from the vehicle (which may include chassis dyno results), there's more information available about how the vehicle is performing. However, because this process is iterative, it also means it can be time consuming for both the end customer and the tuner, because the vehicle needs to have data recorded from it as part of the iterative process. In the context of a “dyno tune”, dyno rates are generally assessed by the hour and can be upwards of $300/hr just for the dyno time. On top of that you have software licensing costs. Most of the commercially available calibration packages charge a per-vehicle license fee, which, in extreme cases can exceed $600 / vehicle (e.g. if ECU unlocking services are required). And, tuners don't work for free – in many cases they charge an hourly rate as well. A full “customized” tune can easily cost upwards of 4-5 times what an off-the-shelf programmer might cost. The biggest drawback to the “customized” tuning process is that there's no common standard of quality – in other words, there are some really good tuners and there are some who are tuners simply by virtue of owning a laptop and the tuning software. There's also the issue of tuners being proficient on one type of vehicle, and the opposite on another. Anybody with a laptop and a few hundred dollars can become a “custom tuner”, and some of these tuners associate their competence with the software they are using as a common brand rather than the actual quality of their end product. The companies producing the calibration software don't really take any action to make a distinction here, but at the same time they cannot enforce a common standard of quality, they're just producing a tool that other people use, and in some cases the tool is incomplete. As anybody who deals in knowledge and information as a trade, it's expected that there's some level of 'mysticism' around how a tuner knows what they do and where they learned their techniques from. Aside from their personal experience, this can come from many places including tuning schools, training materials, online discussion boards, discussions with other tuners, reverse engineering of other tuning products or studying tunes from other tuners. Sourcing knowledge this way without fully understanding the “how” or “why” can allow unknown and potentially undesireable artifacts to get into an end customer's tune. The other issue is that a “customized” tune is completed at a specific point in time, under specific conditions (vehicle, environment, etc). For a customer that stays within a specific locale and only drives their vehicle under similar conditions (e.g. seasons), this may not be an issue, but does the tuner know how your vehicle is going to perform in the middle of winter at sea level if they “custom” tuned it in the middle of summer at 4000 feet altitude? The larger kit manufacturers that provide a calibration with, say, their supercharger kit probably do, but a tuner at a dyno shop probably doesn't. If there are problems with it in different environments, it may be necessary to perform follow-up tuning adjustments which is time consuming, and potentially disruptive to the end customer. Finally, there's no guarantee the software tools being used for this process are complete and provide access to all the constructs in the ECU required to properly calibrate the vehicle. In fact, there's no guarantee even the OE software that runs in the ECU has all of the necessary constructs to properly support the calibration of a heavily modified vehicle. E.g. the software engineers that wrote the ECU software for a naturally aspirated Corvette would not have put much consideration into what would happen if the aftermarket installed a supercharger. TRIFECTA tuning, defined Ok, so we have defined “canned” tuning, and “customized” tuning. Where does TRIFECTA fit on the spectrum? It turns out TRIFECTA products borrow from the advantages of each while offering other advantages that don't come with either type of tuning. Advantage: Pricing TRIFECTA products, in most cases, are priced to be competitive with off-the-shelf “canned” programmers. These programmers are lower cost because the manufacturers of them are not directly subject to the per-vehicle licensing fee like the “customized” tuners are, and there's no tuner looking to monetize the service. They also benefit from economies of scale. TRIFECTA similarly enjoys a low overhead because all of TRIFECTA's flash software was written in-house, is not reliant on any 3rd party, and as such is not subject to expensive licensing fees. Advantage: Ease of Use, little hassle TRIFECTA products are installed using a Windows based laptop combined with a USB cable that interfaces with the vehicle via the OBD-II port. This is also how most “customized” tuning software works as well. The ease of use advantage is that with TRIFECTA, the calibration work is already done. There's no learning curve for how to use a calibration software package, you just install a simple Windows based application, load the calibration, and you're finished. Advantage: Expertise, on your vehicle TRIFECTA doesn't offer tuning products for vehicles they haven't exhaustively calibrated and spent significant amounts of time with. Many other companies in the industry will ask for “R&D vehicles” from the market, or even experiment on customer vehicles as a generally accepted procedure while TRIFECTA makes an enormous investment in having a fleet of vehicles for ongoing campaigns. We share engaging content of these vehicles through the web and social media. Advantage: Support for modifications, small and large TRIFECTA has an aggressive directive to build a knowledge base of support for aftermarket modifications. Again, while retaining an appealing price-point, TRIFECTA can and does also support modifications that, through any other tuning company, would have to be supported through “customized” tuning. Need a tune for that custom aftermarket sheet metal intake for your Chevrolet Cruze? No problem, we've got you covered. Advantage: Tuning products can be “individualized” or “dialed in” if needed Many TRIFECTA products offer an Elite tier. This is a higher priced tier that provides “remote customized” tuning support for parts we may not have an off the shelf calibration for. TRIFECTA's team of calibration engineers has vast experience in virtually every type of modification out there and allows customers to leverage this knowledge through the Elite tier. Advantage: If you do have a problem, we've got you covered TRIFECTA offers products at the price-point of a “canned” tune but provides diagnostic services, knowledge, experience, and capabilities that can rival factory-authorized service centers. In the majority of cases, if there's a vehicle that isn't running correctly, it's because there's a problem with the vehicle (though in some cases software incompatibilities can reveal issues that need to be resolved at the tuning level). That doesn't mean you're out in the cold, though. Regardless of what product tier our customers have, TRIFECTA provides full diagnostic services and support as needed to help track down the issue, whether it's vehicle, software, or tuning related. Advantage: We abuse our cars on the dyno, drive them across the country Can your tuner claim and prove they put several hundred dyno pulls on their Cadillac ATS-V then drove the car across the country through various climates and environments before selling you a product? TRIFECTA can. The aggregation of the data gathered from this type of process makes our products more thorough. Advantage: Common standard of quality Our calibrations are developed by the same engineers, with the same processes and level of experience. When you buy TRIFECTA, you're buying a standard of quality you can't be assured to get from any arbitrary tuner that promotes themselves by saying they use the same tools as other tuners do. Many “customized” tuners learn by tuning other people's vehicles. Is yours the first? Second? TRIFECTA has been in the industry for nearly 15 years (at time of writing). Advantage: Innovation and exclusive features These are some of the exclusive features that TRIFECTA offers that can't be had anywhere else, and in some cases that's because these features don't even exist in the OE software. TRIFECTA approaches performance and reliability from a holistic standpoint and will add exclusive features where it makes sense from a customer demand or reliability standpoint. Driver Selectable Vehicle Modes (“DSVM”) - changes the performance level or drive feel on the fly with the cruise control switch Power-by-Mode (“PBM”) – An extension of DSVM for select platforms with factory drive-mode selectors, we can assign different power levels to each mode, as well as change driving characteristics (pedal feel and shift strategy): e.g. ATS-V Tour: Stock power, stock shifting Sport: Moderate power increase over stock, performance oriented shift strategy Track: Full power, performance oriented shift strategy Advanced Rail Pressure Management (“ARPM”) - Dynamically adjusts airflow limits based on the DI fuel system saturation level 2017+ Transmission Recalibration (“T87A”) – We can recalibrate your “T87A” controlled transmission (8, 9, 10-speed) without removing the TCM, let alone paying for an expensive unlock procedure. Performance AutoStop Mode (“PASM”) – Allows the driver to enable a performance-oriented auto-stop mode which, in most cases, inhibits auto-stop from enabling for improved performance character, when desired (triggered by the cruise control arming button) AutoStop Deletes - A new product line that simply disables the factory “autostop” feature! Introduced as a fuel-savings feature, “autostop” allows the vehicle to shut the engine off when the vehicle is stopped, and quickly restart it when the driver is ready to move the vehicle, but not all vehicle owners feel it works smoothly enough. Advantage: Continuous innovation and improvement “Customized” tuning is largely a one-time deal. You get tuned, that's it. There may be minor adjustments as needed, but there's no real infrastructure in place to give out “mass updates” that make improvements to customers. Because of this, and frankly the lack of a financial aspect, there's little incentive to put a dedicated focus on innovation and improvement. TRIFECTA views continuous innovation and improvement as core tenets of business. The Chevy Cruze launched in late 2010 - at the time of writing that was over 8 years ago. To this day, we still have an active campaign to improve the feature-set of the product and we make these improvements available to every customer. Disadvantage: Can't use commercial tuning software to modify TRIFECTA On the surface, some may feel this is a “vendor lock-in” strategy. That might be the case if we didn't provide a means to uninstall the product and restore the capability of it to be used with other tuning software or OE updates – but we do. At the time of writing, the commercially available tuning software packages require the vehicle to have either completely OE software, or a modified derivative of OE software. A TRIFECTA tuned vehicle is neither, but can easily be restored to OE software using our tools. Disadvantage: TRIFECTA's bar is high for supporting aftermarket modifications While our “remote custom” tuning services give our engineers the tools to tune virtually any build remotely, consideration is given to whether we can do it in a timely manner and smoothly for the end customer. The only thing that's worse than declining to tune a project for a customer is accepting the project (and customer's money), and then not being able to deliver a quality tuning product in a timely manner. We believe expectations need to be set appropriately and being able to deliver quality is more important than selling a calibration to a customer. Disadvantage: TRIFECTA's data logging format is proprietary (like everybody else's) TRIFECTA's flash utility can also generate “data logs” from customer vehicles, but the data is stored in a proprietary format - in the same way other commercial tuning software uses a proprietary format. In fact, it's considered a modern computing security concern to use a proprietary format to protect the authenticity of the information being transmitted. Unlike other software, however, we do not provide a public viewer for this data, and rely on a series of non-public tools to process the log data. Having said that, data logging of a TRIFECTA calibration can still be performed using any tool that supports data logging the vehicle, though, and we can provide recommendations that are compatible with our flash cable for customers that wish to review the data from their vehicle as well. Conclusion We're not here to say that TRIFECTA is a perfect fit for every tuning situation, because we aren't. The goal in this writing is to put some definition around the terms sometimes used to describe our products. On the surface we do look like a “canned tune”. We're priced like one, we provide many of the advantages of one, but we also bring to the table many of the advantages of “customized” tuning. But, in the end, the intersection of these benefits combined with our exclusive features and offerings put TRIFECTA into a class of its own.

-

TRIFECTA: More fuel for your direct-injected engine!

TRIFECTA Performance commented on TRIFECTA Performance's article in News

Hey @Chris75, the injectors in this post were provided to us by one of our aftermarket partners, and are not publicly available at this time. We look forward to supporting your future plans though! -

-

The TRIFECTA Autostop Disable Powertrain Calibration is meant for 100% stock vehicles. No individualizations or support for parts that do not function on factory calibration (if you have such modifications, be sure to check with us prior to placing your order). Includes a TRIFECTA flash loader. Specifications of the TRIFECTA Performance Autostop Disabe ECM software reprogramming: -”Autostop” feature permanently disabled -Retains all GM OE diagnostics and ECM functionality -Retains all OE error code reporting and functionality -The TRIFECTA flash loader and Transparency featureset optionally does not increment the ECM write counter or increment entries in the flash history -Return to stock functionality included with flash loader Installation Notes: -Estimated installation time of ~20 minutes Currently supported vehicles are: 2016+ Cadillac ATS 2.0L Turbo 2016+ Cadillac CTS 2.0L Turbo 2017+ Cadillac XT5 3.6L 2017+ Buick Enclave 3.6L 2016+ Buick Encore Sport 1.4L Turbo (LE2) 2016+ Chevrolet Cruze 1.4L Turbo (LE2) 2016-2017 Chevrolet Malibu 1.5L Turbo 2017+ Chevrolet Traverse 3.6L 2018+ Chevrolet Equinox 1.5L Turbo 2018+ Chevrolet Equinox 2.0L Turbo 2017+ GMC Acadia 3.6L 2018+ GMC Terrain 1.5L Turbo 2018+ GMC Terrain 2.0L Turbo with more models to follow... if you don't see your model listed, please Contact Us!

-

@joeker12, we'll be sending out the first kits by or before the end of March, with a firm release date to follow. @mallenjackson, we won't be doing pre-orders, but we do have an internal "wait list" going, which we can add you to if you like. 👍

-

Factory size s 45.9mm. We will be sending out the first 58mm kits by the end of Q1 2019. 👍 We're still working on this one, so wheel size hasn't been finalized, but it is most definitely in the works!

-

TRIFECTA presents: Cadillac ATS-V MY2016+ Performance Calibration

TRIFECTA Performance commented on TRIFECTA Performance's article in News

Hi @joe1278, The EZ Flash User Guide contains step by step instructions, as well as screen-captured videos of the EZ Flash installation and flashing process recorded in real time: https://www.trifectaperformance.com/ezflash -

- 2 comments

-

- 1.4l turbo

- cruze

-

(and 2 more)

Tagged with:

-

91 octane is all that is needed, and in fact the car will run on 87 octane if needed. Power will simply scale down accordingly. This turbo will actually be packaged as a kit which will include 60lb injectors, giving you all the headroom you'd need for E85. Our ability to control fuel pressure via reprogramming the Fuel Pump Control Module (FPCM) negates the need for an upgraded pump as well. You can read more about our research into injector options and reprogramming the FPCM here:

-

The 2019 model year for the Chevrolet Colorado and GMC Canyon is largely a “carryover” from 2017 and 2018 model year, with the 2017 model year introducing the “next generation” 3.6L V6 (RPO: LGZ) engine as an update of the previous 3.6L V6 (RPO: LFX) and the 8L45 8 speed automatic transmission. The TRIFECTA performance calibration for the 2019 Chevrolet Colorado and 2019 GMC Canyon is unchanged versus the 2017 and 2018 Chevrolet Colorado / GMC Canyon product. Below is a list of feature highlights (V6): Gains of up to +41 ft-lbs and +28 WHP under the curve (and +18 ft-lbs and +10 WHP peak on 91 octane) Full 8 speed transmission recalibration WITHOUT TCM removal and/or unlocking Three way Driver Selectable Vehicle Modes (DSVM): Sport, Eco, and Tow/Haul Support for aftermarket modifications and hardware Performance Active Fuel Management (PAFM) – no V4 transitions in Sport Mode (Ad+, Elite) Full restore-to-stock functionality included Product updates provided at no charge (includes support for OE software updates) To order your TRIFECTA performance recalibration for your 2019 Chevrolet Colorado or 2019 GMC Canyon, please visit our store: https://www.trifectaperformance.com/store/category/66-colorado/ https://www.trifectaperformance.com/store/category/150-canyon/

-

TRIFECTA: Announcing tuning support for 2019 Chevrolet Sonic

TRIFECTA Performance posted a article in News

The 2019 model year for the Chevrolet Sonic is largely a “carryover” since the 2017 exterior and interior update, with one key change: the 1.8L I4 (RPO: LUW/LWE) engine is no longer available. The TRIFECTA performance calibration for the 2019 Chevrolet Sonic and 2019 GMC Canyon is unchanged versus the 2012 through 2018 Chevrolet Sonic product. Below is a list of feature highlights: Gains of up to +51 ft-lbs and +44 WHP Full transmission recalibration (automatic transmission vehicles) “No Lift Shift” feature retains boost through performance shifts (manual transmission vehicles) Two way Driver Selectable Vehicle Modes (DSVM): Sport, and Eco Support for aftermarket modifications and hardware Full restore-to-stock functionality included Product updates provided at no charge (includes support for OE software updates) To order your TRIFECTA performance recalibration for your 2019 Chevrolet Sonic, please visit our store: https://www.trifectaperformance.com/store/category/125-14l-turbo/ -

-

TRIFECTA: For your ATS-V. More power. Meaner sound. Zero rasp.

TRIFECTA Performance commented on TRIFECTA Performance's article in News

Hi @Michael Plummer, The units shown in the article were created for testing, but did not contribute any appreciable gain to power, nor did the packing in the resonators hold up to the heat after extended abuse on the dyno. We are looking into testing a unit with a different design.